We had the opportunity to take a behind the scenes and navigational bridge tour of the Viking Neptune. The three top officers on the ship are the Master of the Vessel who commands the ship and is primarily responsible for all navigational aspects of the voyage; the Chief Engineer who is responsible for all mechanical aspects of the ship; and the Hotel General Manager who is responsible for everything else — food service, state rooms, housekeeping, bars, guest relations, laundry, ship supplies, and entertainment staff all are under his supervision; 401 of the 465-person crew are in this department. All of three of these gentlemen are very busy, yet they all make themselves available to answer guest questions and even conduct tours. We were pleasantly surprised to discover that Hotel General Manager Ronald Schweighardt personally leads the behind-the-scenes tour of this state-of-the-art, $400 million dollar vessel. He doesn’t do this just once per voyage, but several times each week ensuring that all guest who might be interested in the tour get an opportunity to take a tour.

The tour began with a walk through of the Neptune’s main galley (kitchen). All Viking cruise ships are subject to US health standards and are subject to unannounced health inspections in any US port of call. Apparently, US health standards for ships are the most stringent in the world so that is the standard that Viking follows. The ship employees 101 Chefs and Cooks who prepare over 5000 meals per day primarily from this galley. Our first impression was the wonderful smells, but even more impressive was the cleanliness of the galley.

Everything served on the ship is prepared on the ship to include all baked goods. A few interesting facts about the food and bar service: over 2000 eggs are served every day, 400 liters or 106 gallons of beer are served each day, and 550 bottles of wine are consumed each day by approximately 900 guests and 465 crew. As for food waste, all waste, to include bones are placed in a pulper system water added and placed in a holding tank. The food waste is then released into open ocean waters, where permitted, as fish food.

We moved from the kitchen down to deck A. Deck A is a crew only area and is the first deck above the water line. There is a passageway that runs the length of the ship and is referred to as “I-95″, referring to the interstate highway that runs down the east coast of the USA. ”I-95” is the heartbeat of the ship. All of the ship’s stores are on this deck, some of the crew cabins are here, and the engine control room is also found on deck A. This is also the deck that Tender Boat operations are conducted from in ports where the ship must anchor offshore to embark and disembark passengers. Ronald shared several funny stories regarding ship supply issues that he has had to resolve over the years. One involved a wine shipment not showing up at a US port and having to rent a truck and go to a local Costco Store, with cash in hand, to purchase the wine. The crew was shocked to discover while checking out that a membership card was required to make the purchase. Fortunately, the driver of the truck they rented had a Costco membership and was able to make the purchase on the ship’s behalf. He also noted the supply rooms were very full and some even overflowed into the “I 95” passageway. Because this is a world cruise with predominantly North American passengers there are some provisions North Americans prefer that can only be procured in the US or Canada. For example, Diet Coke is only available in the US, the rest of the world drinks Coke Zero, but to ensure the American customers have Diet Coke, enough was brought onboard in Fort Lauderdale to get us through the 138-day voyage.

Next, we toured the engine control room, but no pictures were allowed during this stop. This was an interesting stop as virtually all of the ships systems are controlled from here. The room has a “Star Wars” feel to it. There are control panels with multiple large screen monitors around the room. Here the ship’s engineering staff monitors everything from engine and navigational control systems to water desalination and sewage processing to electrical distribution. The ship is able to produce 40 tons of water per hour from two desalination plants, more than enough to provide the 350 tons of fresh water needed each day. Similar to food waste, grey water (non-sewage liquid waste) is held in tanks, chemically treated and released back in the ocean bacteria free. Sewage or “black water” is held in holding tanks and pumped off at various ports of call for disposal. Everything is state of the art, the engine department only requires 32 people to operate and maintain the ships systems.

From here we moved down to Deck B, which is the first of two decks located below the water line. This is where the engine room and Kully’s favorite stop, the ship’s laundry is located. We weren’t able to visit the engine room, but we did get to see the Laundry Room. There are two sections in the laundry, one that deals with ship linens — towels, tablecloths and bedding and the other that deals with clothing – Crew uniforms, crew personal clothing and guest clothing. We were most impressed with the linen side of the operation. Here there were several large commercial washers and dryers plus a very large machine used to dry and fold sheets and tablecloths. Kully tried to find one on Amazon, but no luck.

We weren’t told how many sheets, towels and table clothes are process each day, but we know it’s a lot and this state-of-the-art facility makes it possible to do so very efficiently.

Viking has a very stringent recycling program. All trash is segregated for recycling, cardboard is crushed and bailed, glass is crushed and all is off loaded at designated ports for processing.

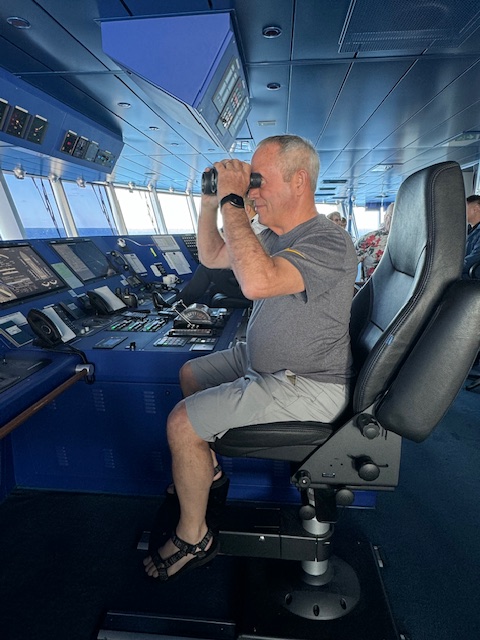

The Navigational Bridge tour was conducted by one of the Officers of the watch. Like the behind the scenes tour, this tour is conducted periodically throughout the voyage so that all interested guest get an opportunity to visit the bridge. This was the first time I’ve ever been on the bridge of an Ocean Liner, so I was really excited to see what the bridge looked like. The bridge is where the ship’s navigational crew “drives” the boat. Obviously, there is more to it than just steering and controlling the throttle. The ships course must be determined, set and maintained; obstacles avoided; harbors navigated; and docking operations/maneuvers executed. Most of the navigational operations are automated and carried out by two officers per watch. More are on the bridge during critical maneuvers and docking operations.

In the first picture above are the controls located in enclosed flying bridge that are used when the ship is docking. The third picture shows the officer of the watch in control of the ship. The ships average speed is maintained between 16 and 17 knots, with a top speed of 19 knots. Notice the steering wheel in the center, this is the ship’s helm or manual steering wheel. The crew normally keep it covered to avoid accidently bumping while on autopilot. There is also an emergency bridge located on the top deck of the ship providing a redundant capability in case the primary bridge is damaged or incapacitated.

“What a wonderful thought that some of the best days of our life haven’t happened yet.” Anne Frank

Leave a comment